The Importance of Accurate BOM in Production

Waveon

An accurate bill of materials (BOM) is the backbone of any production line. It ensures every component, quantity, and specification is spot-on, preventing costly delays, inventory mishaps, and quality issues.

Discover how managing a BOM accurately transforms efficiency, streamlining everything from procurement to product assembly. Also, get tips to ensure your bill of materials is precise and updated in real time to boost profitability.

6 Reasons Why an Accurate BOM is Important in Production

A precise bill of materials acts as your production process blueprint, steering procurement, inventory, and manufacturing processes efficiently. Let’s dive into the key benefits of using an accurate BOM in production.

1. Prevents Production Delays

An accurate BOM provides a comprehensive list of all important raw materials, components, individual parts, and subassemblies. It offers real-time stock visibility and prevents production delays due to missing parts or last-minute product sourcing.

Since 49% of supply chain interruptions lead to significant planning challenges, accurate material planning is key as it cushions production and prevents delays. It helps keep the production plan on track, lowers downtime, and improves efficiency.

2. Ensures High Product Quality

An accurate BOM ensures you consistently have the right materials and components for production, helping you meet industry standards and reduce defects and variations in your final product.

What's more? A well-maintained BOM boosts traceability. If you are in the food business, traceability can help lower the risk of food recalls by 50-95% by letting you track where each ingredient came from and which batch.

It makes it easier to comply with quality standards like ISO 9001 and FDA regulations with accurate and up-to-date BOM data.

3. Controls Costs

With an accurate BOM, you will only order the necessary materials and components, preventing excess inventory and minimizing waste. You can also avoid expedited last-minute shipping costs for any missing parts. An optimized BOM prevents cost overruns by matching material orders with your actual production needs.

4. Streamlines Procurement and Inventory

An accurate BOM ensures you order materials in accurate quantity at optimal times, preventing unnecessary stockouts, overstocking, or production delays.

Overstocking ties up your capital and you incur 20%-30% additional carrying costs on the excess inventory. However, with an accurate BOM that facilitates efficient stock optimization, you can reduce your inventory carrying costs by accurately forecasting demand and maintaining lean inventory levels.

5. Improves Communication Across Teams

An accurate BOM boosts functional communication across procurement, production, and engineering teams, reducing production defects and costly rework.

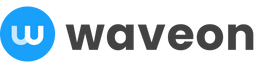

With 73% of production teams citing that inefficiencies in the product communication process could hamper technology gains, an accurate BOM becomes necessary.

It helps teams remain focused and aligned by correctly defining materials, part numbers, and assembly documentation. This ensures engineers design accurately, procurement sources are optimal, and production assemblies are efficient.

What's more? Integrating digital BOM using product lifecycle management (PLM) or ERP systems provides you with instantaneous updates. It ensures each department has access to the latest material specifications.

Choose the right BOM software to increase real-time visibility and collaboration among teams.

6. Improves the Time to Market

The availability of accurate materials and components lets you accelerate assembly, reduce product rework, and shrink material waste. It speeds up the product development process and marketing.

Besides, an accurate BOM allows you to swiftly resolve issues as your team can promptly identify defective or missing components without significantly affecting product supply.

Maintain an Accurate BOM with Top-Notch ERP Systems

In manufacturing, a slight misstep or a missing component can throw your entire production line off schedule. But an accurate BOM saves the day. It keeps all things under control with each material accounted for.

Start using our BOM management template to manage multi-level components and automate your production quantity calculations. Sign-up today to begin your free trial of our no-code ERP solution 一 Waveon.